LX, LY, LZ Lever Clamps

The JIT-SR product line allows world class manufactures to achieve the highest level of reliability in single-minute die and mold exchange processes.

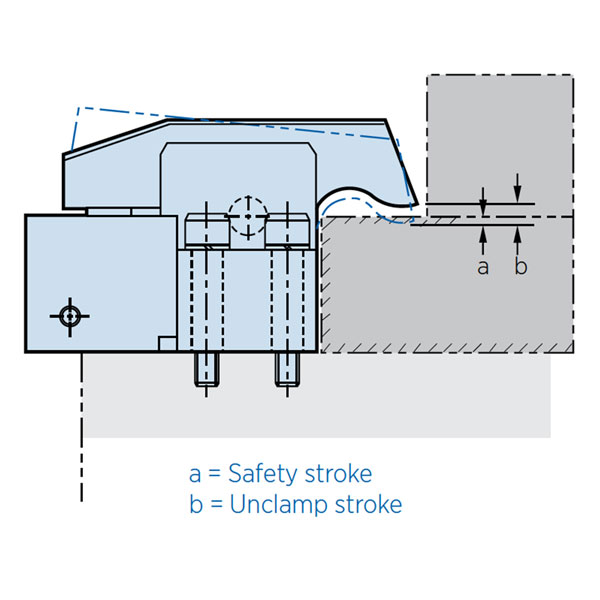

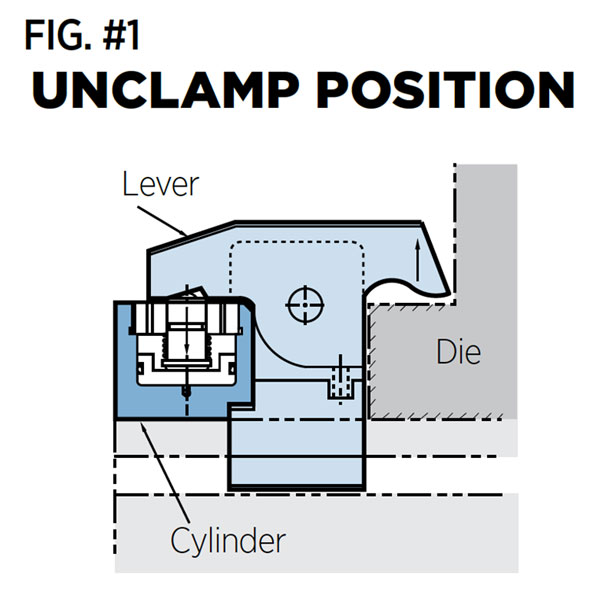

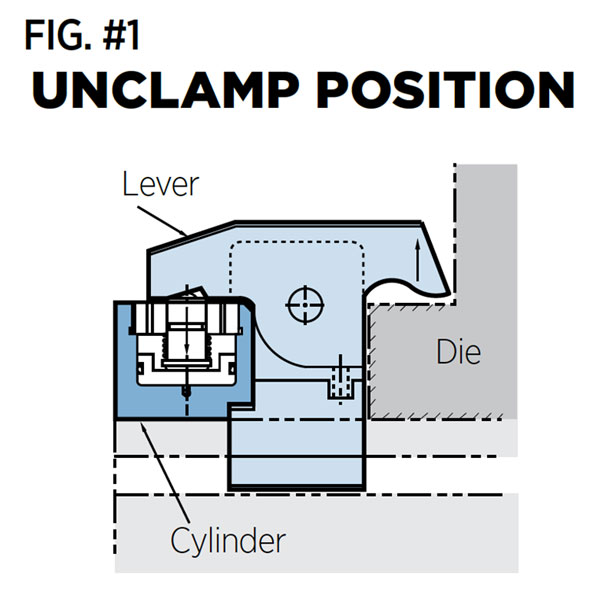

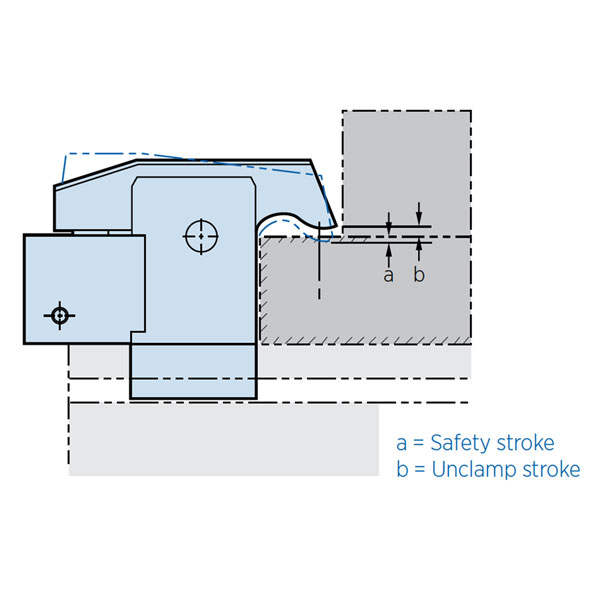

Using a single-action spring return cylinder acting on a lever arm, this lever style clamp hydraulically secures the die base to the press bolster or slide.

| Model | Max. Working Pressure |

|---|---|

| LX | 13.8 MPa (2000 PSI) |

| LY | 18.1 MPa (2600 PSI) |

| LZ | 24.5 MPa (3600 PSI) |

The JIT-SR Advantage:

- No U-cut necessary on die

- Suitable for lower die clamp

- Applicable for injection molding

- Available at various tonnages and machined to customer-specified T-slot specifications.

- Available as a flange mounted unit (F-type), eliminating the need for T-slots.

- Machined from a single forged block for added strength

- Unique split style construction between the cylinder and the lever section eliminates uneven wear to the T-slot by uniformly distributing the clamping force and providing stable surface contact.

- Optional modular style lever-operated check valve which maintains hydraulic pressure in the clamp for 21 hours without a primary power source.

- Optional proximity/limit switch for die shoe detection

- Available in “Non-Touch” auto slide models.

Designed, engineered, and manufactured to the highest standards of quality and reliability, JIT-SR hydraulic clamps are the standard-bearers for Total Quick Die Change (TQDC) and Total Quick Mold Change (TQMC) systems.