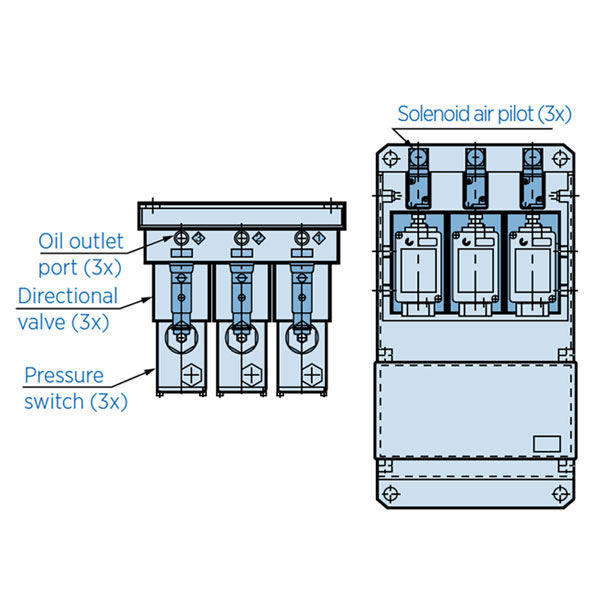

VF Valve Unit VF-S, VF-P, VF-M

The JIT/SR product line allows world class manufacturers to achieve the highest level of reliability in single-minute die and mold exchange processes

The Posi Seal® Valve units represent the industry benchmark for safety and reliability. These positive sealing hydraulic directional control valves are applicable for a variety of hydraulic circuits and valve configurations that are integral to the operation of die clamps and die lifters in a Quick Die Change system.

Each circuit with pressure switch and integral non-leak check valve. All hydraulic and pneumatic connections manifolded to eliminate piping. Electrical devices are prewired to a NEMA 13 class terminal box. Optional compact unit without the pre-wired terminal box for installations with limited space.

Enhanced safety features are engineered into every aspect of the unit for maximum quality, predictability, and peace of mind.

| Model | Variations and Customizations |

|---|---|

| VF-S | Operated with single solenoid, air-piloted, spring return valve for each circuit. Double solenoid option is available. |

| VF-P | Provide air-pilot port for each circuit to be operated by external air-pilot valve. |

| VF-M | Operated with manual, air-piloted valve with push-turn handle for safe |

The JIT/SR Advantage

- Customizable to your system requirements and specifications

- Solenoid valves provide an electrical interlock, enhancing safety

- Pressure switches are wired to a remote panel and interfaced with the press control to stop the press in the event of a pressure loss.

- These valve units are leak-free so that check valves will maintain pressure even if the pump is stopped temporarily.

- Pressure switches continuously monitor hydraulic pressure in each circuit and are pre-wired with the solenoid into an oil-tight junction box with a numbered terminal strip.

All connections are manifolded for ease of installation

Optional manifolded relief valve can be stacked on the assembly to prevent excess build-up of pressure due to high temperatures.